有机废气脱附-吸附催化燃烧装置

1.1 工作原理

1.1 Working Princeples

-----------------------------------------------------------------------

■ 1.1.1 催化法是一种传统的有机废气治理技术,国外早在上世纪四十年代***已经应用于有机废气的治理,国内从上世纪七十年代开始应用,是目前我国机废气治理的主要技术之一,在目前我国有机废气治理设备中,催化燃烧净化设备约占总数的30%左右。因此本规范制定以后可以规范我国有机废气治理中接近30%的工程技术和设备,在工艺设计。设备制造.工程建设检验、运行维护与管理等各个方面全面提高我国OCs治理水平,必将极大地推进我国固定源有机废气的治理减排工作。

■ 1.1.1 Catalysis is a kind of traditional organic waste gas treatment technology, abroad in the early 1940 s has been applied to the management of organic waste gases, domestic application since the 1970 s, is one of China's main machine flue gas treatment technology, in at present, the organic waste gas treatment equipment, catalytic combustion purification equipment for about 30% of the total. Therefore, this code can regulate nearly 30% of the engineering technology and equipment in China's organic waste gas treatment, in process design. Equipment manufacturing, engineering construction, inspection, operation, maintenance, management and other aspects of the comprehensive improvement of China's OCs governance level, will greatly promote China's fixed-source organic waste gas treatment and emission reduction work.■ 1.1.2 催化燃烧工艺装置在日本、美国和西欧国家被广泛地应用于VOC的治理,工艺设备非常成熟,相关的技术标准和使用规范已非常完善,一些大公司都有自己的企业标准,对工艺设计,催化剂的性能要求、反应器制造和工程控制措施等都有详细的规定。

■ 1.1.2 Catalytic combustion devices in Japan, the United States and Western Europe countries have been widely applied to the governance of VOC, process equipment very mature, related technical standards and specifications used has very perfect, some big companies have their own enterprise standards, the process design and performance requirements of the catalysts, reactor manufacturing and engineering control measures are detailed rules.

■ 1.1.3 目前的OCs的治理技术中,催化燃烧技术发展较早,技术上也相对成熟,对于大多数有机污染物而言是一种行之有效的治理方法,因此在VOCs的治理中得到了广泛应用。早期的催化燃烧技术主要用于高浓度或者高温排放的有机污染物的治理,由于对空气的加热升温需要耗费大量的热能(电加热或者燃料加热),在大风量。低浓度的OCs治理中运行成本过高,因此近年来发展了针对低浓度有机废气净化的蓄热式催化燃烧技术( Regenerative Catalytic Oxidizer简写为RCO)。

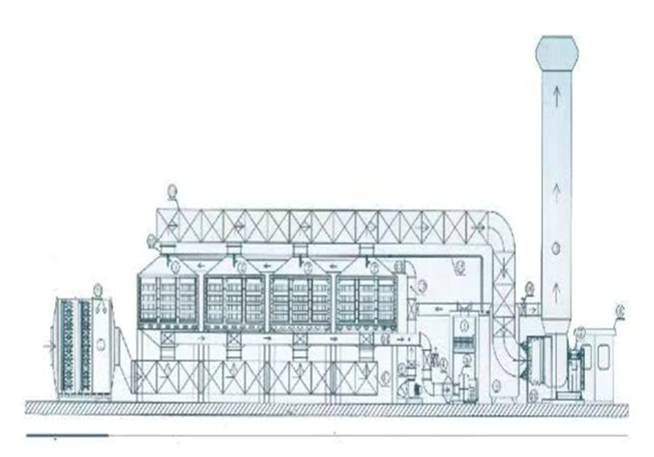

■ 1.1.3 The technology of the current governance of OCs, catalytic combustion technology development earlier, technology is relatively mature, for most organic pollutants (pops) is an effective management method, therefore the VOCs has been widely applied in the management. The early catalytic combustion technology was mainly used for the treatment of organic pollutants discharged at high concentration or high temperature. Due to the heating of the air, a large amount of heat energy (electric heating or fuel heating) was required to be consumed in large air volume. High cost of operation in treatment of low concentration of OCs, so in recent years developed for low concentration organic waste gas purification of Regenerative Catalytic combustion technology (Regenerative Catalytic Oxidizer shorthand for RCO). ■ 1.1.4 蓄热式催化燃烧技术是在催化燃烧技术的基础上增加了一套热能储存与再利用装置。通常利用蜂窝状的陶瓷体作为蓄热体,将催化反应过程所产生的热能通过蓄热体储存井用以加热待处理废气,充分利用有机物燃烧所产生的热能,从而达到节能的目的,和常规催化燃烧技术相比,蓄热式催化燃烧技术可以大大降低设备运行功率,主要应用于较低浓度的有机废气的净化(一般在500-3000mg/m之间), 国内外的研究与实践已经证明,对于有机废气的治理,畜热式催化燃烧技术是比较经济有效、应用前景广阔的净化技术之一。中科院生态环境研究中心在上世纪九十年代初研制过蓄热式催化燃烧装置,并进行了试用,但由于设计和设备加工技术不过关,特别是在高温操作下切换阀门易损害,该技术未能推广应用。同时期美囯恩格尔哈德公司***木材生产工艺中所排放的有机废气设计了一种蓄热式催化燃烧装置,但未见在其他行业推广使用。上世纪末日本三菱公司设计了利用移动阀切换的蓄热装置,采用具有高蓄热能力的陶瓷蜂窝体,很好地解决了这个问题,并进行了实际应用,成为目前发达国家有机废气治理的主体技术之一。例如3M公司用RCO技术处理含丁酮等溶剂的废气,通用汽车公司用RCO技术处理含苯乙烯的废气,飞利浦电子公司用RCO技术处理含丙酮、甲苯、丁酮等的废气。

■ 1.1.4 Regenerative catalytic combustion technology adds a set of heat energy storage and reuse device on the basis of catalytic combustion technology. Usually use honeycomb ceramic as a regenerator, the heat energy produced by the catalytic reaction process through the regenerator storage Wells for heating gas to be processed, make full use of the combustion heat generated by the organic matter, so as to achieve the purpose of energy saving, compared with the conventional catalytic combustion technology, regenerative catalytic combustion technology can greatly reduce the operating power equipment, mainly used in purification of organic waste gas of low concentration (generally between 500-3000 mg/m), The research and practice at home and abroad have proved that for the treatment of organic waste gas, the catalytic combustion technology is one of the more economical and effective purification technologies with broad application prospects. The ecological environment research center of the Chinese academy of sciences had developed a regenerative catalytic combustion device in the early 1990s and tried it out, but the technology failed to be popularized due to poor design and equipment processing technology, especially the damage of switching valves under high temperature operation. During the same period, the United States engelhard company designed a regenerative catalytic combustion device for the organic waste gas emitted from the wood production process, but it has not been widely used in other industries. At the end of last century, mitsubishi corporation of Japan designed a heat storage device using mobile valve switch, and adopted a ceramic honeycomb body with high heat storage capacity, which solved the problem well. For example, 3M USES RCO technology to treat waste gas containing butanone, general motors USES RCO technology to treat waste gas containing styrene, and philips electronics USES RCO technology to treat waste gas containing acetone, toluene, butanone, etc.

1.2 活性炭吸附-脱附催化燃烧技术

1.2 Activated Carbon Adsorption+ Desorption Catalytic Combustion Technology

1.3 活性炭吸附-脱附催化燃烧技术

1.3 Activated Carbon Adsorption+ Desorption Catalytic Combustion Technology

技术特点

1、PLC全身动化控制,配套可操作触摸屏,人机互动性高,节能省力

2、采用无火焰氧化,安全高效,全机体采用防爆设计,并且可接入现有的大型中控系统;

3、高性能蜂窝陶瓷载体贵金属催化剂,催化活性高,性能稳定、使用寿命长,阻力小

4.高性能活性炭吸附剂,比表面积大,吸脱附性能好,过风阻力小,极适合于大风量下使用

5、根据废气分析数据,吸附床内可配套消防系统,充分******设施安全

6、活性炭吸附塔及催化燃烧室配泄爆膜片,当系统内部压力异常升高,泄爆膜片破裂,保护吸附塎及催化燃烧室因内部压力过载而发生重大事故

7、设置LEL监测连保护,严格控制进入系统中有机废气浓度低于其******极限下限值的1/4多重安全保护系统:非稳态控制、温度预警、停机警报及故障应急处置措施等,在大中型厂况中可实现中央控制监管

1.3 活性炭吸附-脱附催化燃烧技术

1.3 Activated Carbon Adsorption+ Desorption Catalytic Combustion Technology

Technical features:

1. PLC whole body motion control, supporting operation touch screen, high man-machine interaction, energy saving;

2. It adopts flameless oxidation, which is safe and efficient. The entire body is explosion-proof and can be connected to existing large central control systems

3. High performance honeycomb ceramic carrier precious metal catalyst with high catalytic activity, stable performance, long service life and low resistance

4. High-performance activated carbon adsorbent, with large specific surface area, good adsorption and desorption performance, low over-wind resistance, and is very suitable for use under high air volume;

5. According to the exhaust gas analysis data, the fire protection system can be configured in the adsorption bed to fully guarantee the safety of the facility.

6. Activated carbon adsorption tower and catalytic combustion chamber with venting explosion diaphragm。

7. LEL monitoring chain protection is set up the system below 1/4 of its explosion limit.

8. Multiple safety protection system: unsteady control, temperature warning, shutdown warning and fault emergency measures, etc., can realize central control and supervision in large and medium-sized plants.

1.4 沸石转轮浓缩+催化燃烧技术

Zeolite Rotation Wheel+Catalytic Combustion Technology

1.4.1 工艺流程图

1.4.1 Process Flow Chart

1.4 沸石转轮浓缩+催化燃烧技术

1.4 Activated Carbon Adsorption+ Desorption Catalytic Combustion Technology

1.4.2 技术特点:

1.VOCs废气通过疏水性沸石浓缩转轮后,能有效被吸附于沸石中,达到去除的目的

2. 经过沸石吸附的挥发性有机物的洁净气体,直接通过烟囱排放到大气中,转轮持续以每小时1-6转的速度旋转,同时将吸附的挥发性有机物传送至脱附区

3. 脱附区中利用一小股加热气体将挥发性有机物进行脱附,脱附后的沸石转轮旋转至吸附区,持续吸附挥发性有机气体

4. 脱附后的浓缩有机废气送至焚化炉进行燃烧转化成二氧化碳及水蒸气排放至大气中

1.4 沸石转轮浓缩+催化燃烧技术

Activated Carbon Adsorption+ Desorption Catalytic Combustion Technology

1.4.2 技术特点

1.4.2 Technology Features:

1.After passing through the hydrophobic zeolite concentration runner, VOCs waste gas is effectively adsorbed in zeolite to remove the waste gas.

2.The clean gas of volatile organic compounds adsorbed by zeolite is discharged directly into the atmosphere through the chimney, and the rotating wheel continuously rotates at the speed of 1-6 revolutions per hour, while transferring the adsorbed volatile organic compounds to the desorption zone.

3. In desorption zone, a small stream of heated gas is used to desorption volatile organic compounds. After desorption, the zeolite wheel rotates to the adsorption zone to continuously adsorb volatile organic gases.

4.After desorption is completed, the concentrated organic waste gas is sent to an incinerator for combustion and conversion into carbon dioxide and water vapor to be discharged into the

atmosphere.